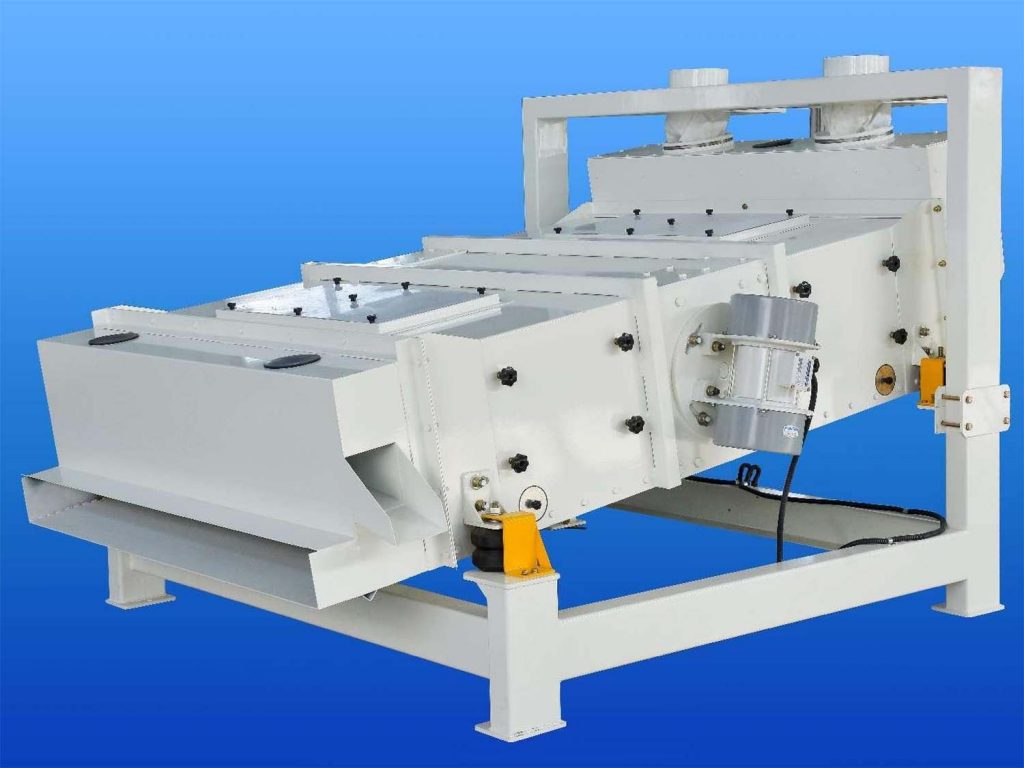

The self balancing vibrating screen stands out among many screening devices and is the ideal choice for grain silo enterprises.

High Screening Efficiency

Advanced Vibration Technology

The self balancing vibrating screen uses advanced vibration balancing technology. This technology keeps the screen body in a stable balance during vibration. Compared to traditional vibrating screens, it offers more uniform and stable vibration. This effectively avoids screening dead zones and material accumulation caused by uneven vibration. Its wide adjustable vibration frequency range allows precise matching with different grain material characteristics.

Innovative Screen Mesh Design

The self balancing vibrating screen features an innovative screen mesh tensioning and fixing system. This reduces screen mesh slackening and deformation. It not only extends the screen mesh's lifespan but also ensures stable screen hole size during screening, improving screening accuracy.

Multidimensional Advantage Analysis

Multifunctional Applicability

In the grain silo screening field, the self balancing vibrating screen shows strong multifunctional applicability. Besides the conventional particle size screening, the device can perform multiple additional functions with special screens and accessories. For example, it can remove impurities, stones, and clean grain during the screening process.

Integrated Intelligent Control System

The self balancing vibrating screen incorporates intelligent control elements with an advanced control system. This system integrates sensor technology, automated control, and data analysis to monitor the equipment's operation and screening parameters in real-time. By installing vibration, temperature, and material flow sensors at key points, the system automatically adjusts vibration frequency, amplitude, and screen mesh tension. This achieves automated and intelligent control of the screening process.

Low Equipment Operating Costs

For grain silos, stable equipment operation is crucial. The lightweight frame facilitates installation and mobility, while high rigidity ensures no deformation during long-term, high-intensity screening. This extends the equipment's lifespan and reduces maintenance costs.