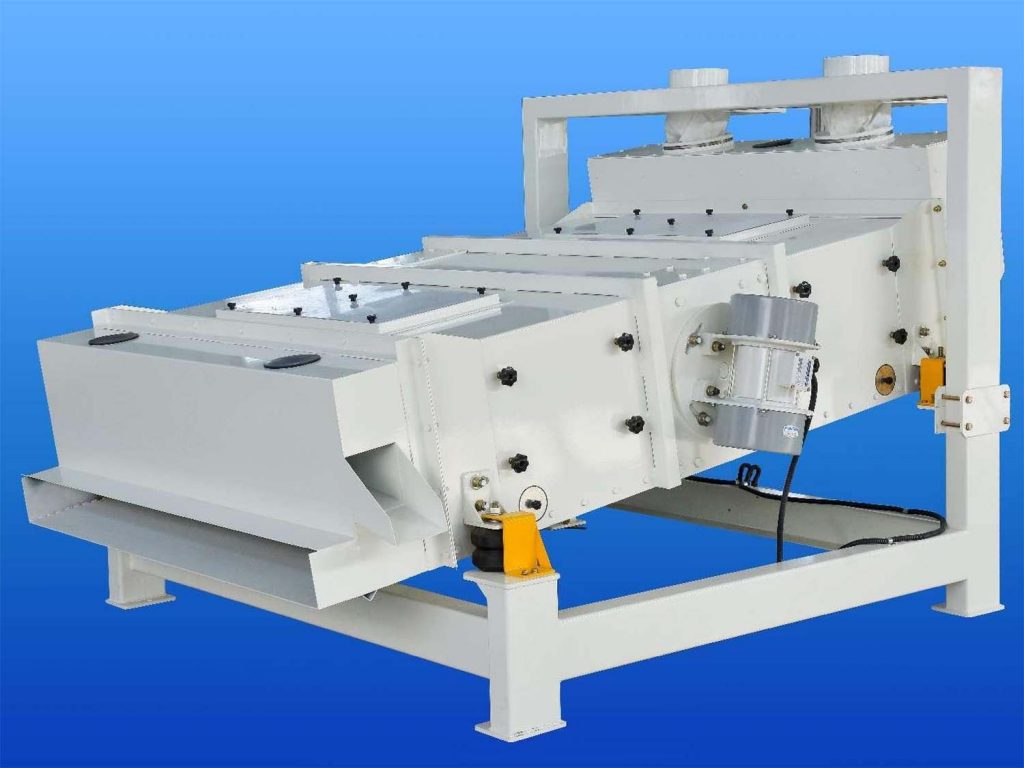

In modern grain storage management, the application of the self balancing vibrating screen significantly enhances the efficiency and quality of grain screening, making it an indispensable key device for grain silos.

Removing Impurities to Ensure Grain Quality

Precise Separation of Various Impurities

The self balancing vibrating screen uses its unique vibration balancing technology to produce stable vibrations. This effectively removes large impurities from grain, such as stones and clumps of soil, and also finely screens out small impurities like wheat bran and rice husk fragments. The vibration frequency and amplitude can be adjusted according to grain characteristics, ensuring precise separation of impurities for different grain varieties and safeguarding the storage of high-quality grain.

Increasing Grain Purity

Before grain enters the silo, the self balancing vibrating screen strictly screens it. After removing impurities, grain purity is significantly improved. This effectively prevents mold and pests caused by impurities during storage, extends the shelf life of grain, and ensures the quality and safety of stored grain.

Grading to Meet Different Needs

Precise Grading by Particle Size

The self balancing vibrating screen can precisely grade grain based on particle size. In grain silo management, by adjusting the screen mesh size, grain is divided into different grades according to its size, meeting the market's demand for grain of different sizes. For example, wheat can be graded into several sizes for different processing purposes, such as flour milling and feed production.

Optimizing Grain Utilization Value

Grain, after grading, can be reasonably allocated for different uses, enhancing its utilization value. Grain with larger particles can be used for processing high-value-added products, while smaller particles can be used for other processing purposes. This optimizes the allocation of grain resources and improves economic efficiency.

Improving Grain Silo Work Efficiency

Automated Screening Process

The self balancing vibrating screen achieves an automated screening process. Compared to traditional manual screening, it significantly increases screening efficiency. In grain silo operations, the self balancing vibrating screen can run continuously and stably, quickly completing the screening of large quantities of grain. This reduces labor costs and intensity, enhancing the overall work efficiency of the grain silo.

Integrated Management System

Managers can monitor the equipment's operation and screening progress in real-time through a monitoring system. They can adjust screening parameters promptly to ensure a smooth screening process, further improving the modernized management level of the grain silo.