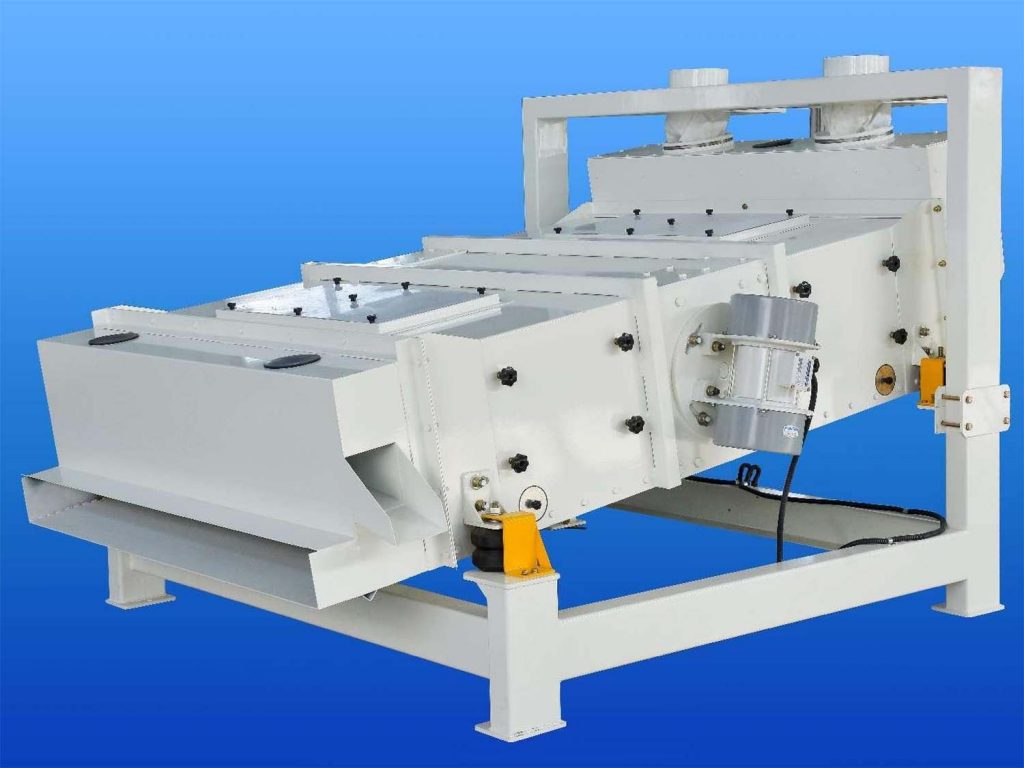

In the grain screening process, the self balancing vibrating screen plays a crucial role. However, to ensure the long-term stable operation of the equipment, regular and scientific maintenance is essential. This article will explore the key points of maintaining a self balancing vibrating screen to enhance production efficiency.

Regular Maintenance Schedules and Content

Quarterly Maintenance

Conduct a comprehensive inspection of the self balancing vibrating screen every quarter. Focus on checking if the screen mesh is loose or damaged, and replace it promptly to prevent a decline in screening effectiveness. Also, inspect all connection bolts to ensure they are tight, avoiding faults caused by loose parts. Clean the screen holes to prevent clogging by impurities, which can affect ventilation and screening efficiency, thereby extending the equipment's service life.

Semi-Annual Maintenance

Perform an in-depth maintenance of the lubrication system every six months. Add an appropriate amount of specialized lubricating grease to key areas such as vibrator bearings to reduce component wear and ensure smooth equipment operation. Inspect the vibration-dampening rubber springs, and replace them if signs of aging, deformation, or breakage are detected to ensure stable equipment operation.

In-Depth Maintenance Highlights

Annual Overhaul

Schedule a comprehensive overhaul once a year, involving a thorough disassembly and inspection of the equipment. Replace excessively worn bearings, seals, and other wear-prone parts to ensure the equipment's sealing and lubrication. Carefully inspect the internal windings and insulation of the vibration motor, and repair or replace the motor if any damage is found to prevent production interruptions due to motor failure.

Corrosion Protection

Regularly apply corrosion protection to the equipment's metal surfaces. After cleaning off dust, oil, and rust from the equipment, recoat it with rust-proof paint or a corrosion-resistant coating to enhance its corrosion resistance, especially for self balancing vibrating screens operating in humid or harsh environments.

Daily Maintenance Precautions

Pre-Startup Inspection

Develop a habit of checking the equipment before each startup. Ensure the screen mesh is intact, all bolts are tight, and the feed inlet is clear of debris. Also, check the lubrication status to ensure sufficient lubricating oil (grease) at all lubrication points, preventing equipment damage due to insufficient lubrication upon startup.

Post-Shutdown Cleaning

After shutdown, promptly clean residual material from the equipment to prevent hardening or spoilage. Gently clean the screen mesh and interior of the machine using a soft brush or high-pressure water gun to keep the equipment clean. If any abnormalities are detected, such as small-scale screen mesh damage or slight loosening of parts, repair them immediately to prevent the issue from escalating.