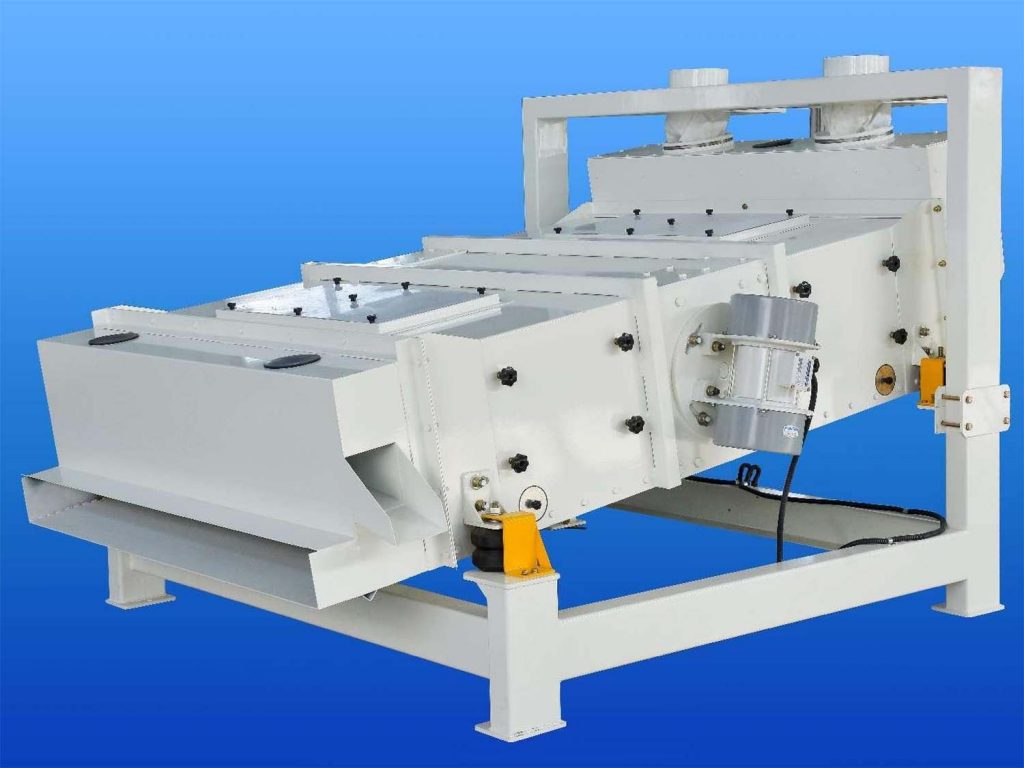

As a key device for grain screening in modern grain silos, proper commissioning of the self balancing vibrating screen is crucial for efficient operation and screening quality.

No-Load Commissioning

Pre-Startup Inspection

Before starting the self balancing vibrating screen, conduct a comprehensive visual inspection of the equipment. After powering on, ensure the main power switch is off. Use a multimeter to measure the equipment's ground resistance, which should be less than or equal to 4 ohms to prevent electric shock and ensure operator safety.

Startup and Observation

Once everything is confirmed, start the equipment. Observe if it starts normally and runs stably. Check if the motor's rotation direction is correct; if it's reversed, promptly swap the phase sequence of the motor power lines. Use vibration and noise meters to monitor vibration and noise levels.

Initial Adjustment

Check if the motor's installation position is accurate. Adjust the motor's vertical and horizontal position to align the excitation force direction with the screen box's movement. Adjust the vibration frequency by changing the angle of the exciter's eccentric blocks; a larger angle results in a lower frequency but higher amplitude.

Load Commissioning

Feeding and Screening

After successful no-load commissioning, begin load commissioning. Start with a small amount of feed and observe the material's distribution and movement on the screen surface. If material accumulates or distributes unevenly, adjust the feed inlet's position and size to ensure even material distribution. Check the screening efficiency, which should be no less than 85%. Low efficiency may be due to improper screen mesh count or insufficient tension.

Screening Effect Assessment and Adjustment

Observe the material's movement trajectory on the screen surface, which should be parabolic without significant jumping or stalling. If the trajectory is abnormal, adjust the excitation force of the vibration motor. A higher excitation force increases the material's jumping height and movement speed on the screen surface. Adjust the excitation force by adding or removing counterweights in the exciter.

Multi-Stage Screening Commissioning

In multi-stage screening applications, commission each screen level sequentially. Check the screening efficiency of each level from top to bottom, ensuring it is no less than 85%. If a level has low efficiency, first check the screen tension and mesh count of that level, then check the screening effect of the previous level to prevent material over-accumulation due to insufficient screening in the previous level.