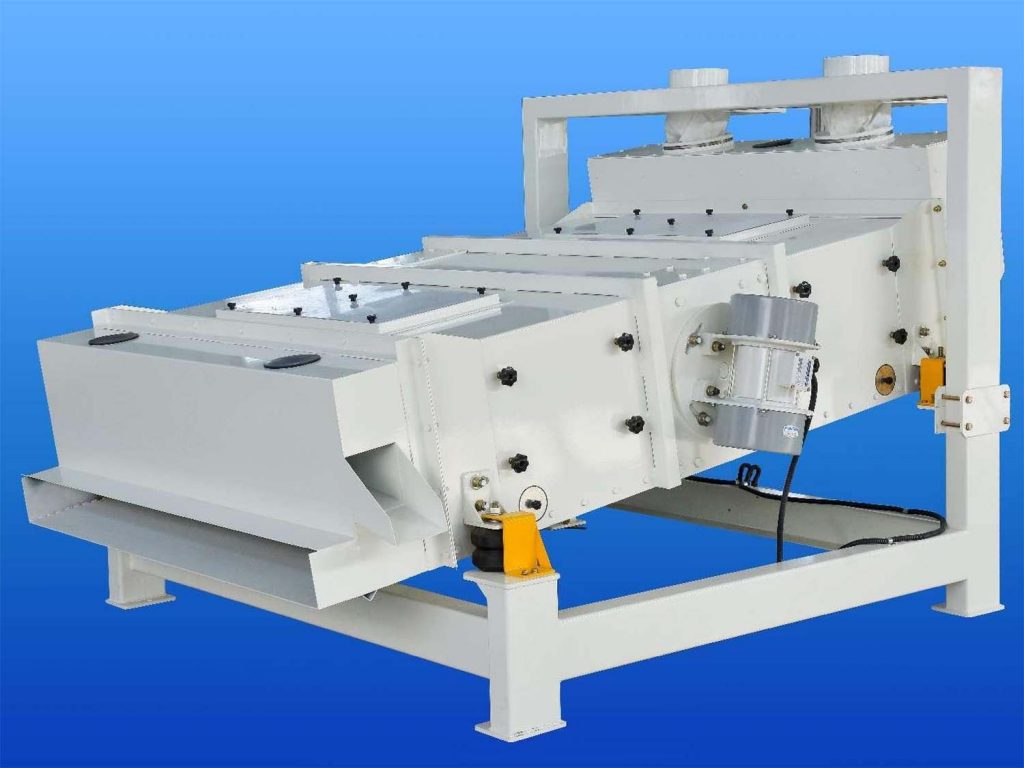

In the grain storage and processing industry, self-balancing vibrating screens are key equipment for efficient grain screening. However, during daily operation, they may encounter some common faults that affect screening efficiency and quality. Here are detailed descriptions of these common faults.

Mechanical Component Faults

Screen Mesh Damage and Slackening

The screen mesh is a core component of the self-balancing vibrating screen, directly affecting the screening results. Slackening of the mesh can reduce screening accuracy and even cause material leakage. These issues usually arise from prolonged use, where the mesh is constantly impacted and worn by materials, or due to insufficient tension during installation.

Vibration Motor Abnormalities

Common vibration motor faults include overheating, unstable speed, and abnormal noises. Overheating may be caused by prolonged overload operation or poor heat dissipation. Unstable speed could be due to worn motor bearings or fluctuating power voltage.

Damping Spring Failure

Damping springs play a crucial role in reducing vibration transmission during operation. Failure of these springs, often caused by long-term exposure to high-intensity vibrations, can lead to spring fatigue, deformation, or breakage. This not only intensifies equipment vibration but may also damage the foundation and surrounding equipment.

Electrical System Faults

Power Supply Issues

Unstable power supply is one of the common electrical problems for self-balancing vibrating screens. Voltage fluctuations can make it difficult to start the equipment or cause abnormal operation, and may even damage the motor and other electrical components. Additionally, power interruptions can halt the equipment suddenly, affecting production schedules and potentially causing material buildup on the screen mesh, making it harder to restart the equipment.

Control Circuit Faults

Faults in the control circuit can prevent the equipment from starting or operating normally. Short circuits and open circuits are common issues in control circuits. Short circuits may trigger overload protection or damage electrical components. These faults may be caused by aged wiring, loose connections, or damaged electrical components.

Other Common Faults

Uneven Feeding

Uneven feeding can lead to an uneven distribution of materials on the screen surface. This may be caused by poor feeder design, malfunctioning feeding equipment, or changes in material properties. Uneven feeding can overload specific areas of the screen mesh, accelerating mesh wear and reducing overall screening efficiency.

Equipment Sealing and Material Leakage

During operation, self-balancing vibrating screens may experience poor sealing and material leakage. This not only causes material waste but also increases the cleaning burden around the equipment. Leakage may be related to loose connections or insecurely fastened screen meshes.