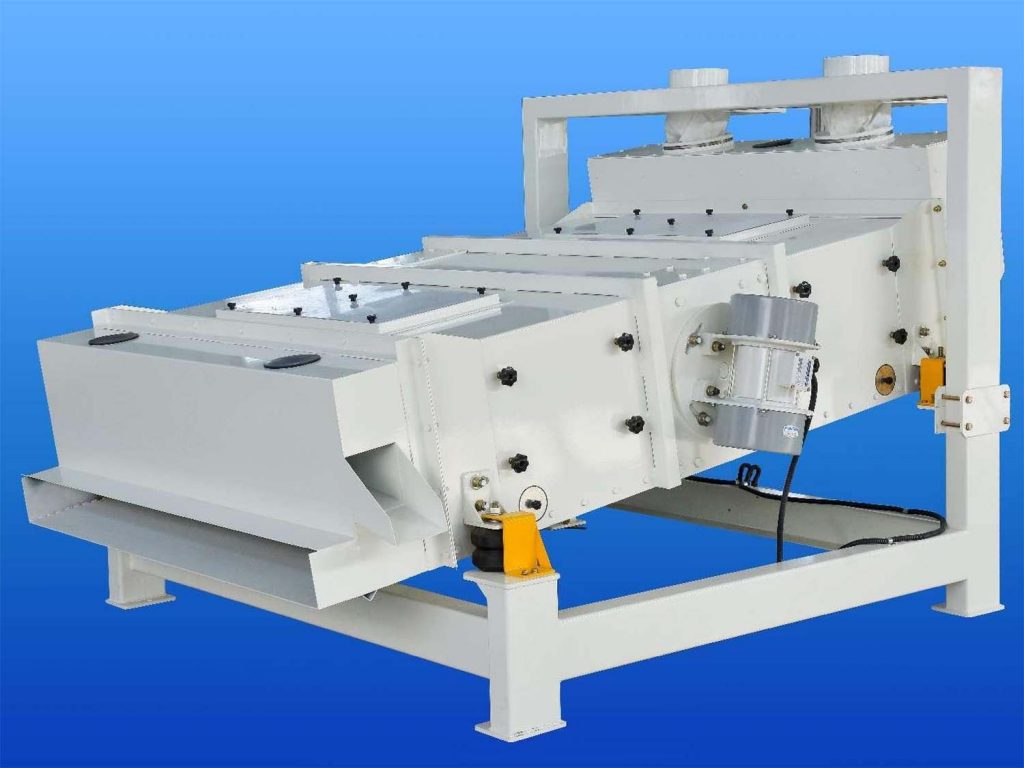

In modern industrial production, the self - balancing vibrating screen, as an efficient screening device, is widely used in grain processing and other fields. Its ingenious structural design is the key to realizing efficient screening. The following will detail the core construction composition of the self - balancing vibrating screen.

Screen Box

Structure and Material

It is usually welded from high - quality steel, such as Q235 or Q345 steel, which has high strength and good stability. The shape and structure of the screen box are designed reasonably to ensure the uniform distribution and smooth flow of materials during the screening process. Its appearance is mostly in the shape of a rectangular prism or cube, and it is equipped with reinforcing ribs inside to enhance the overall rigidity of the screen box.

Function and Role

The screen box not only supports the screen mesh and other components but also guides the movement trajectory of materials on the screen surface through its unique structural design. The internal surface of the screen box is usually specially treated, such as with lining plate protection, to reduce the wear of materials on the screen box and improve the durability of the equipment.

Screen Mesh

Type and Material

It is usually woven from stainless steel wire and has high strength and wear resistance. Common types of screen meshes include square - hole screen mesh, round - hole screen mesh, and rectangular - hole screen mesh. Different types of screen meshes are suitable for different screening requirements. Square - hole screen mesh is suitable for screening materials with larger particle sizes. Round - hole screen mesh is more suitable for screening materials with smaller particle sizes and irregular shapes. Rectangular - hole screen mesh is often used for screening materials with special shapes.

Vibration Motor

Working Principle and Features

It generates exciting force to make the screen box vibrate, thereby realizing the screening of materials. The working principle of the vibration motor is based on the exciting principle of the alternating - current asynchronous motor. It generates an alternating magnetic field between the stator and the rotor, thereby generating exciting force. The vibration motor has the characteristics of compact structure, adjustable exciting force, and convenient maintenance. Its unique design can ensure the uniform transmission of exciting force, keep the screen box balanced during vibration, and improve the screening effect.

Damping Device

Type and Principle

The damping device is an important part of the self - balancing vibrating screen. It can effectively reduce the impact force of the equipment on the foundation during vibration and protect the structural integrity of the equipment and foundation. Common types of damping devices include rubber spring dampers and steel spring dampers. Rubber spring dampers have good damping effects and elastic properties, which can effectively absorb high - frequency vibrations. Steel spring dampers have higher load - carrying capacity and durability, making them suitable for vibration reduction of heavier equipment.