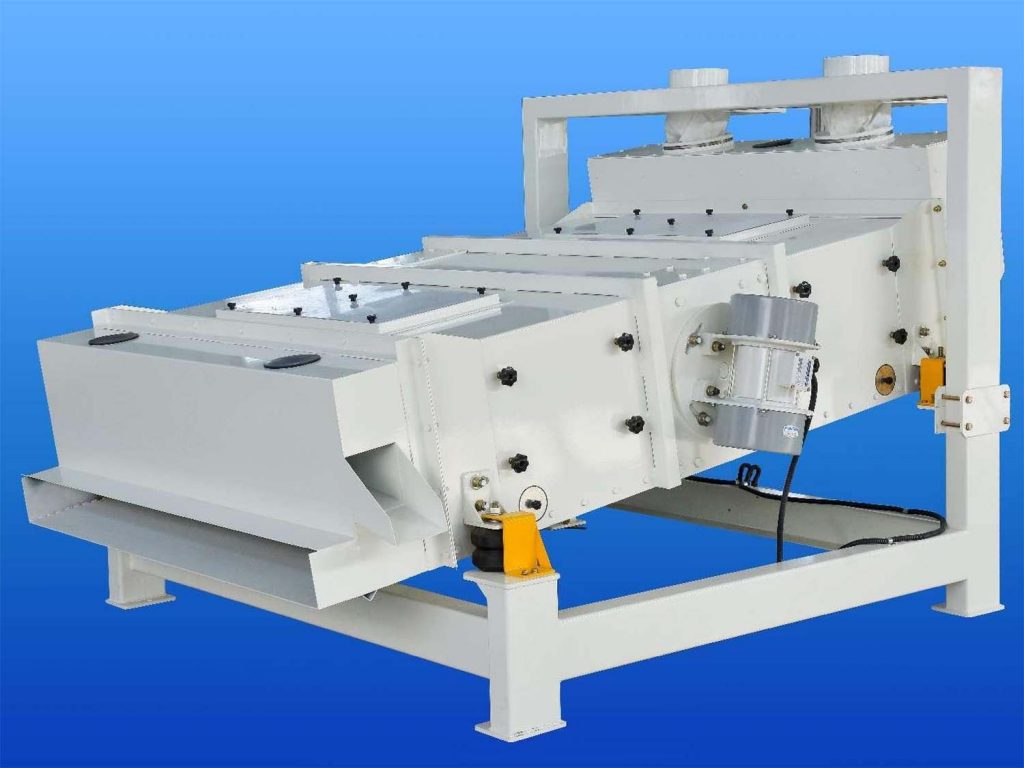

In modern grain storage systems, the self balancing vibrating screen is a high-efficiency screening device. The quality of its installation directly affects screening efficiency and equipment lifespan. Here are the core steps and key points for installing a self balancing vibrating screen:

Foundation and Support Legs Installation

Foundation Construction

The equipment foundation should be flat and sturdy, capable of withstanding dynamic and static loads. The foundation size is determined based on the equipment base dimensions and load, typically 150 - 200mm larger than the base, with a height of 300 - 500mm.

Support Leg Installation

Connect the support legs to the foundation using high-strength bolts, ensuring the verticality deviation of the legs is less than 1/1000. Measure and adjust with a level to ensure even load distribution and prevent shaking during operation.

Screen Mesh Installation and Tensioning

Screen Mesh Installation

After opening the screen box, lay the screen mesh flat on the frame, ensuring the mesh count and hole size meet production requirements. Align the mesh parallel to the support beams, press firmly around the edges to prevent loosening or lifting, and ensure tight contact with the box.

Screen Mesh Tensioning

Use the tensioning device to tighten the screen mesh. Proper tension keeps the mesh flat during operation, avoiding slack or vibration. Apply even force during tensioning to prevent mesh deformation or tearing, enhancing screening efficiency and mesh lifespan.

Vibration Motor Installation and Adjustment

Vibration Motor Installation

Install the vibration motors on both sides using high-strength bolts, ensuring they are level and rotate in opposite directions. The combined excitation force should align with the movement direction. Ensure secure connections to prevent loosening during operation.

Excitation Force Adjustment

Adjust the excitation force by changing the angle of the motor's eccentric blocks; a larger angle increases the force. Typically, the angle is set between 45 - 90°, with an excitation force deviation of less than 5% to ensure uniformity.

Inlet and Outlet Installation and Adjustment

Inlet Installation

Align the inlet with the upper feeding equipment, ensuring a tight, sealed connection to prevent material leakage. Feed material evenly to avoid impacting the screen mesh, extending mesh life.

Outlet Installation

Ensure the outlet smoothly connects with the conveying equipment, with adjustable height and angle to guarantee unobstructed material discharge. Regularly inspect and clean the outlet to prevent blockages.

Lubrication System Installation

Install grease nipples and drain ports at key locations such as bearing housings. Ensure smooth grease injection and drainage for regular lubrication, reducing component wear and extending equipment life.