Among various screening devices, the vibrating screen stands out for its efficient screening capability and is essential in the grain processing industry. Proper configuration of the performance parameters of the vibrating screen is key to achieving efficient screening.

Vibration frequency is a key indicator of the performance parameters of the vibrating screen. A higher vibration frequency allows grain materials on the screen surface to roll and jump more frequently, which helps fine particles pass through the screen holes quickly and improves screening efficiency.

For damp grains or sticky materials, increasing the vibration frequency to 2500 - 3000 times per minute can break the adhesion between materials and enhance screening performance.

Amplitude is another important factor affecting the performance of the vibrating screen. A larger amplitude increases the throwing height of materials on the screen surface, enhancing their dispersion and giving fine particles more chances to pass through the screen holes. However, for fragile grains like soybeans, excessive amplitude may cause grain breakage and affect quality. Therefore, when selecting a vibrating screen, amplitude should be matched reasonably based on grain characteristics and screening requirements.

The screen mesh is a core component of the vibrating screen, and its material and hole size directly affect screening performance. Choosing the right screen mesh material according to the performance parameters is crucial. For example, high-manganese steel screen mesh is suitable for materials with high wear, while stainless steel screen mesh is ideal for fine screening.

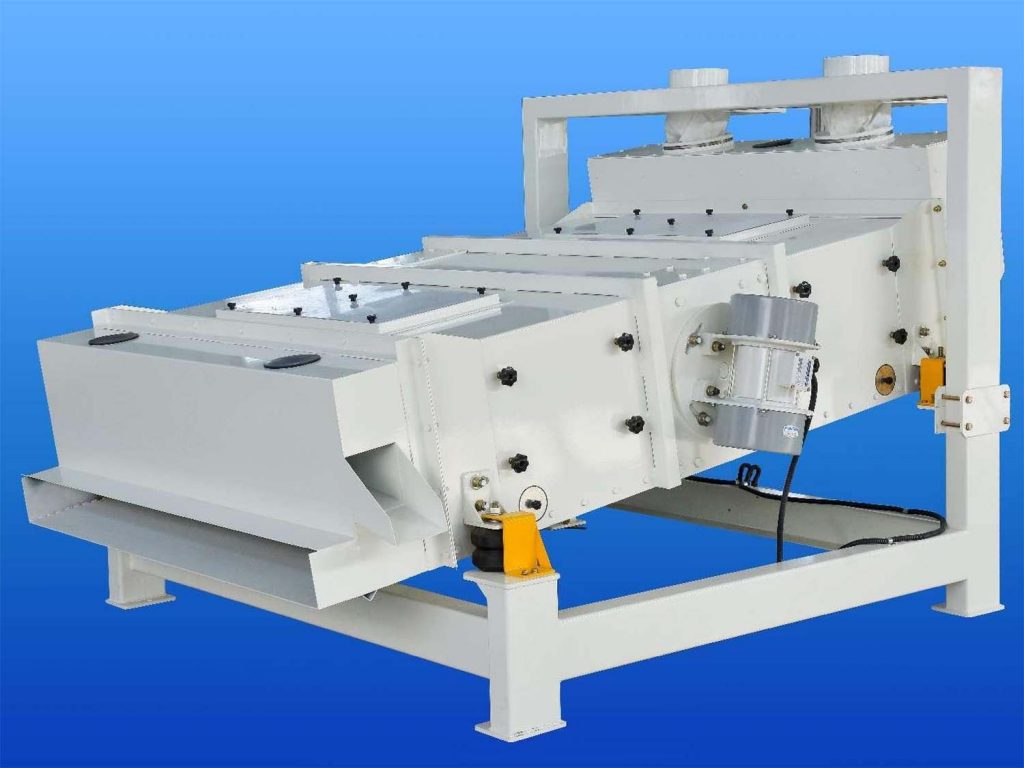

The vibrating screen endures significant vibration and impact during operation, so its stability and durability are important aspects of its performance parameters. High-quality exciters and vibration-damping devices can effectively improve the equipment's operational stability and extend its service life.