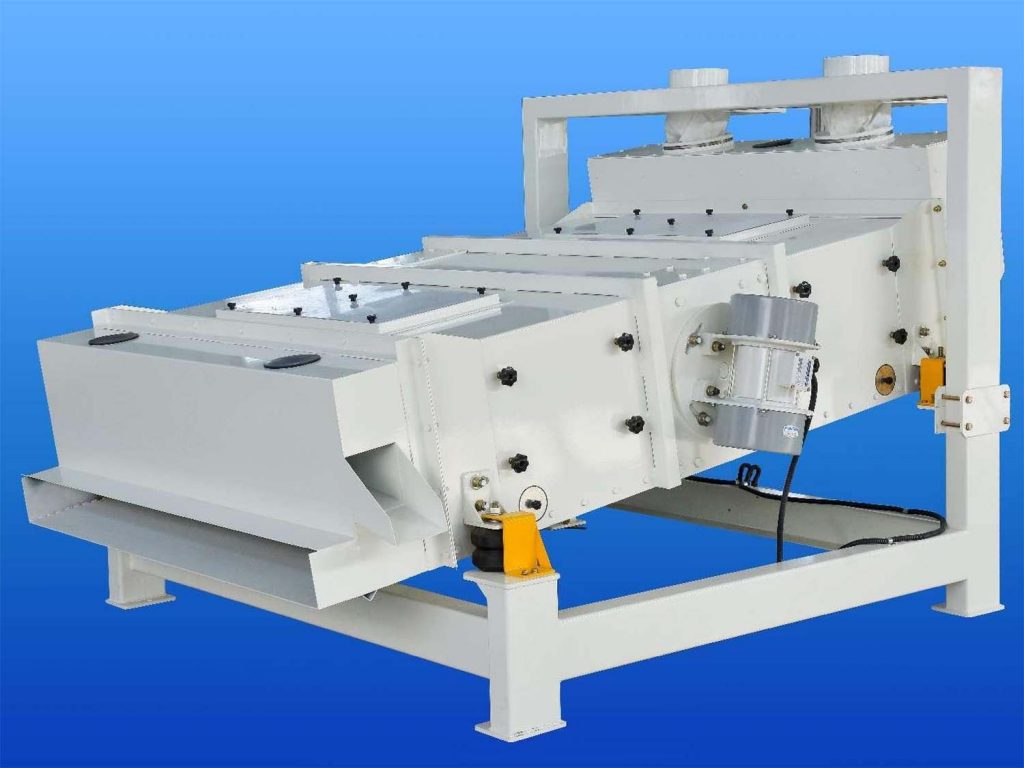

The application effect of the vibrating screen directly affects grain quality and production efficiency. This article will explore the practical application of vibrating screen in the grain field to help relevant enterprises optimize the screening process.

Wheat, a common grain crop, has small and irregularly shaped particles. In the practical application of vibrating screen, for wheat screening, it is recommended to use a screen mesh with a hole size of 1.5 - 2mm and set the vibration frequency between 1800 - 2200 times per minute. Meanwhile, choose an amplitude of 3 - 5mm to effectively separate impurities from wheat while avoiding particle breakage.

Corn has larger and more regular particles, so the screening solution is different. In the practical application of vibrating screen, for corn screening, a screen mesh with a hole size of 3 - 4mm can be selected, the vibration frequency can be appropriately reduced to 1500 - 1800 times per minute, and the amplitude can be increased to 8 - 10mm.

With the development of industrial automation technology, the practical application of vibrating screen in grain processing has integrated intelligent elements. By installing sensors and automated control systems, the vibration frequency and amplitude can be adjusted in real-time according to the actual screening situation of the grain, achieving precise screening. This intelligent control method not only improves screening efficiency but also reduces human operation errors.

In a large grain silo, an intelligent vibrating screen system was adopted. By installing weight sensors and moisture sensors on the vibrating screen, the flow and moisture of the grain were monitored in real-time. When the grain moisture was high, the system automatically increased the vibration frequency to break the adhesion between grains and ensure screening effectiveness.