In grain processing, screening, and many related industries, choosing the right self - balancing vibrating screen is key to improving production efficiency and ensuring product quality.

Clarify Production Needs as the Basis for Selection

Production Scale and Processing Volume

Determining the company's production scale and the volume of material to be processed is the first step in selecting a self - balancing vibrating screen. Production scale directly determines the equipment's processing capacity and screen size.

Material Characteristics and Screening Requirements

Analyzing the physical properties of the material in detail is crucial for selecting the right self - balancing vibrating screen. These properties include particle size distribution, shape, specific gravity, moisture content, and whether it is sticky. The particle size distribution of the material determines the size and shape of the screen holes. For example, for materials with uniform and fine particle size, circular screen holes can be chosen. For irregularly shaped or elongated materials, square or rectangular screen holes are more suitable.

Focus on Equipment Parameters and Performance Indicators

Vibration Frequency and Amplitude

Vibration frequency and amplitude are important parameters that affect the screening performance of self - balancing vibrating screens. Vibration frequency determines the speed at which the material moves on the screen surface. Higher frequency is suitable for screening fine - grained materials, allowing the material to pass through the screen holes more quickly. Lower frequency is suitable for screening coarse - grained materials.

Screen Area and Number of Layers

A larger screen area provides more screening space and improves screening efficiency. The number of screen layers depends on the grading requirements of the material. Generally, the more screen layers, the higher the grading precision that can be achieved. At the same time, it is important to ensure that the area of each screen layer is large enough to guarantee the screening effect.

Pay Attention to Equipment Quality and Reliability

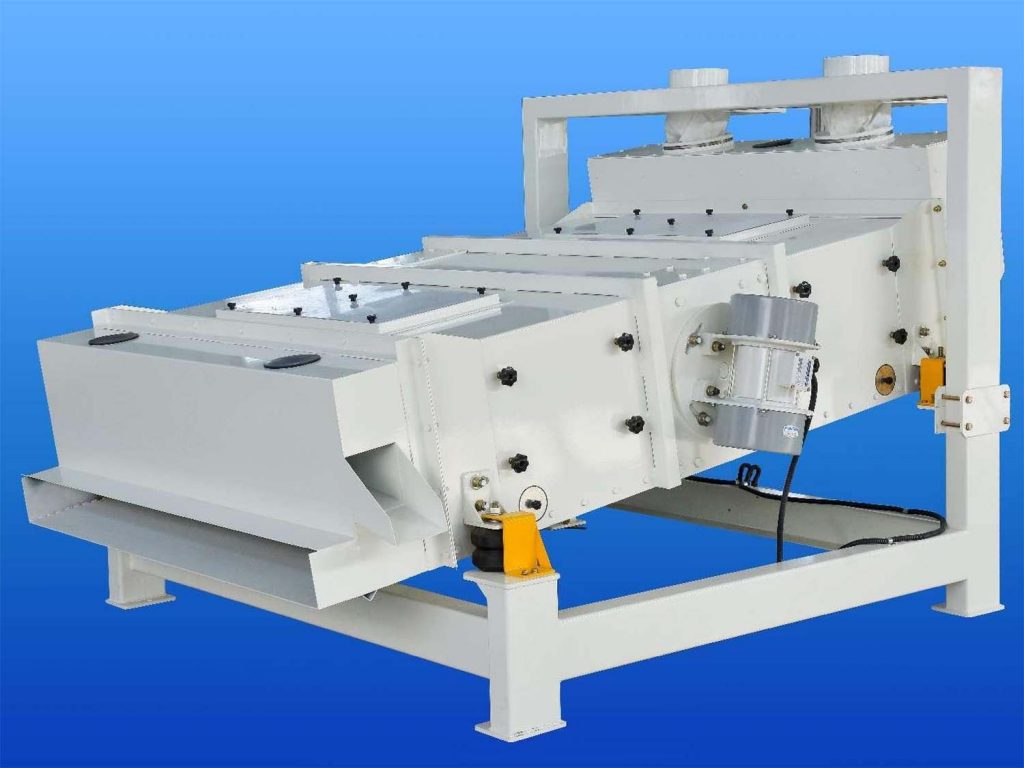

Equipment Material and Structure

High - quality self - balancing vibrating screens should be made of high - strength, corrosion - resistant materials such as high - quality carbon steel or stainless steel to ensure the equipment's service life and stability. The structural design of the equipment should be rational and able to withstand long - term vibration and material impact. For example, a screen box structure made using an integrated welding process is more stable and airtight than one made using riveting or bolted connections. This can effectively reduce the failure rate of the equipment during operation.

Brand and Reputation

Choosing a well - known brand and a self - balancing vibrating screen manufacturer with a good reputation is an important guarantee for ensuring equipment quality and reliability. For example, HKB Machinery has advanced production technology, a strict quality control system, and comprehensive after - sales service. During the selection process, you can understand our equipment performance by checking our customer reviews and visiting our facilities.