In grain processing and screening, the self-balancing vibrating screen is key equipment. Its price is influenced by various factors. Understanding these factors helps businesses make wise purchasing decisions and get good value for money.

Main Factors Affecting Self-Balancing Vibrating Screen Prices

Equipment Specifications and Models

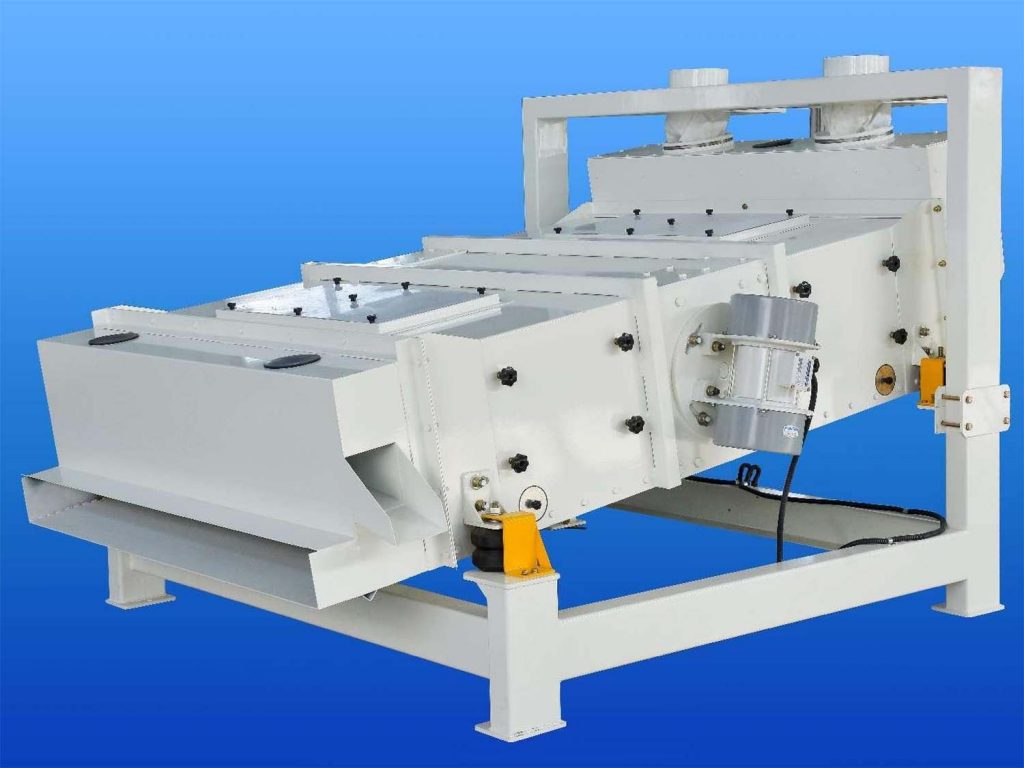

Self-balancing vibrating screens vary in price due to different specifications and models. Large ones, with big screening areas and high capacity, are costly as they meet large-scale production needs. Small ones, for small-scale production or labs, are more affordable.

Equipment Material and Quality

The material and quality of self-balancing vibrating screens directly impact their lifespan and performance. Those made from high-quality steel and high-performance parts are durable and reliable. They can operate stably in harsh conditions, so they are priced higher. For example, food-grade stainless steel screens, with good corrosion resistance, are more expensive than ordinary ones.

Considering the Cost-Effectiveness of Self-Balancing Vibrating Screens

Balancing Price and Performance

Large grain processing businesses can benefit from high-performance, expensive screens. They boost long-term efficiency and product quality, bringing higher economic benefits. Small enterprises or those on a tight budget should choose moderately priced, stable basic screens.

Assessing Long-Term Costs

Besides the initial purchase price, consider long-term costs like energy consumption, wear-and-tear replacement frequency and costs, and maintenance expenses. Some low-priced equipment may have high energy and replacement costs, increasing operational burdens over time.

In contrast, high-quality, reasonably priced self-balancing vibrating screens have a higher initial cost. But they save energy, reduce maintenance frequency and costs in the long run, lowering overall long-term costs and improving cost-effectiveness.