The ventilation design for hopper bottom silos is crucial for ensuring grain storage safety and quality. A scientific design effectively controls internal temperature and humidity. It also minimizes grain loss and extends storage life.

Core Components of Ventilation Design

Fan Selection

Centrifugal fans or axial fans are chosen based on ventilation needs and silo size. Centrifugal fans suit situations requiring higher pressure. Axial fans perform better where larger air volume is needed. Engineers must accurately calculate airflow and pressure to meet grain storage requirements.

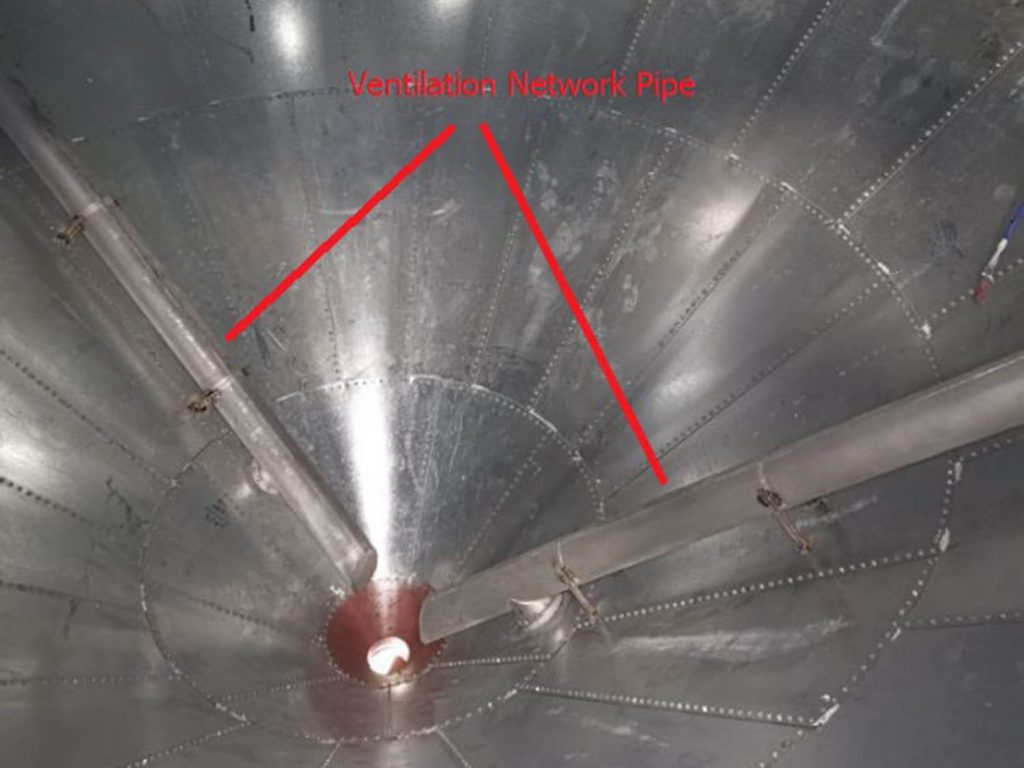

Duct Layout

The outer ring duct runs along the silo wall and guides air around the grain bulk. Meanwhile, the inner ducts extend deep into the grain mass. This combination prevents ventilation dead zones. Air passes evenly through every grain, enabling efficient heat and moisture exchange.

Roof Exhaust Fans and Natural Ventilation Windows

Roof exhaust fans enhance air extraction when necessary. They quickly reduce temperature or humidity inside. Natural ventilation windows add flexibility. During suitable weather, they use natural wind for ventilation, saving energy and protecting the environment. These auxiliary features allow the system to adapt to actual conditions and improve overall performance.

Key Details in Ventilation Design

Choosing Ventilation Modes

Common modes include “cooling ventilation,” “drying ventilation,” and “equalization ventilation.” Cooling ventilation lowers grain temperature and reduces respiration. Drying ventilation removes excess moisture through airflow. Equalization ventilation balances internal temperature and humidity differences. Each mode requires specific fan operation times and airflow settings tailored to actual needs.

Calculating Air Volume and Pressure

Designers determine air volume based on silo capacity and grain type. Usually, airflow should be 1–3 times the silo volume per hour. They also calculate air pressure considering grain resistance and duct friction losses. This ensures even air distribution throughout the grain pile.

Optimizing Ventilation Uniformity

Improving duct layout is key to uniformity. For example, increasing the number of inner ducts and adjusting duct spacing help air reach every part of the grain. Additionally, regular system checks and maintenance prevent blockages in the ducts. These steps maintain consistent ventilation performance.