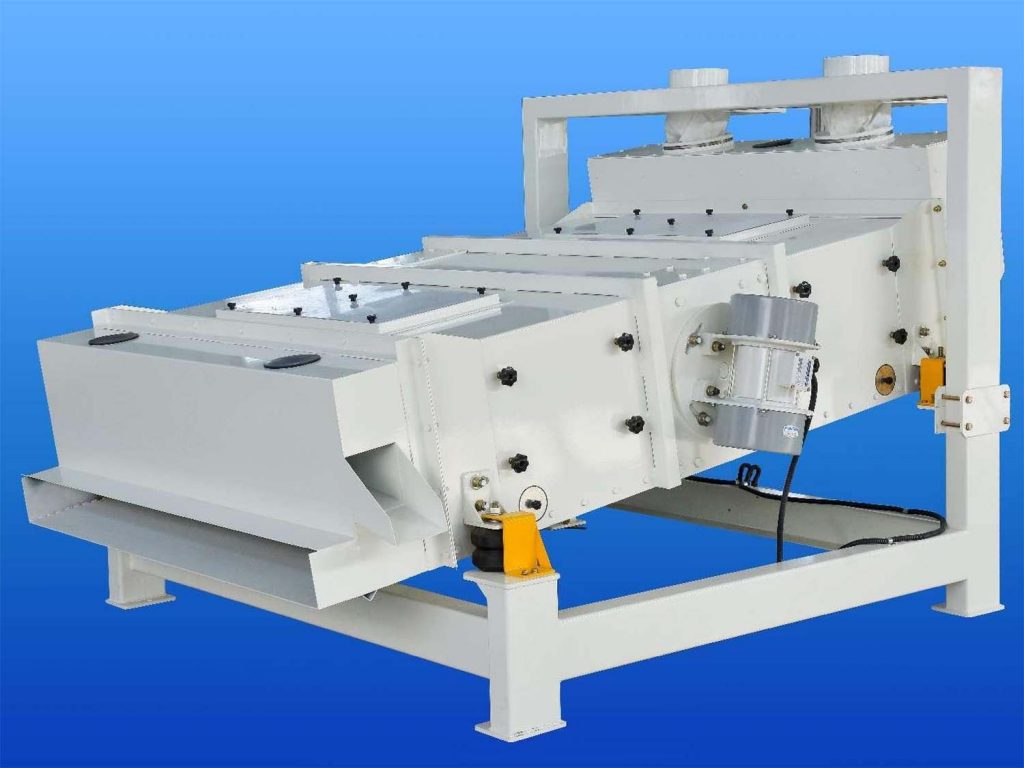

In the grain storage and processing industry, vibrating screens are key devices for ensuring grain quality. However, even the most advanced equipment cannot perform optimally without proper maintenance. This article will explore the essential points for vibrating screen maintenance.

Before starting the vibrating screen each time, equipment inspection is essential. Carefully check if all components are securely fastened, especially critical parts like the screen mesh and bolts. This step is crucial because loose parts can cause abnormal vibrations and noise during operation, and may even damage the equipment.

Continuous monitoring during operation is equally important. Operators need to closely watch the running condition of the vibrating screen, observing whether the vibration of the screen box is smooth and even, and checking for any unusual shaking or noise. If any abnormal conditions are detected, such as sudden changes in the amplitude of the screen box or unusual sounds, the machine should be stopped immediately for inspection. Troubleshoot and resolve the issue before restarting to prevent further damage to the equipment.

The screen mesh, as one of the core components of the vibrating screen, is prone to wear, deformation, and even damage due to the friction and pressure from the grain during long-term use. Regularly inspecting the condition of the screen mesh is vital. Once the wear reaches a level that affects screening accuracy or causes damage, the screen mesh should be replaced promptly to ensure the screening effectiveness of the vibrating screen.

For rotating components of the vibrating screen, such as bearings and motors, regular lubrication should be carried out according to the equipment manual. Generally, bearings should be cleaned and lubricated every 200 - 300 working hours. Proper lubrication ensures the smooth operation of these components, reduces wear, and extends the service life of the equipment.ts.