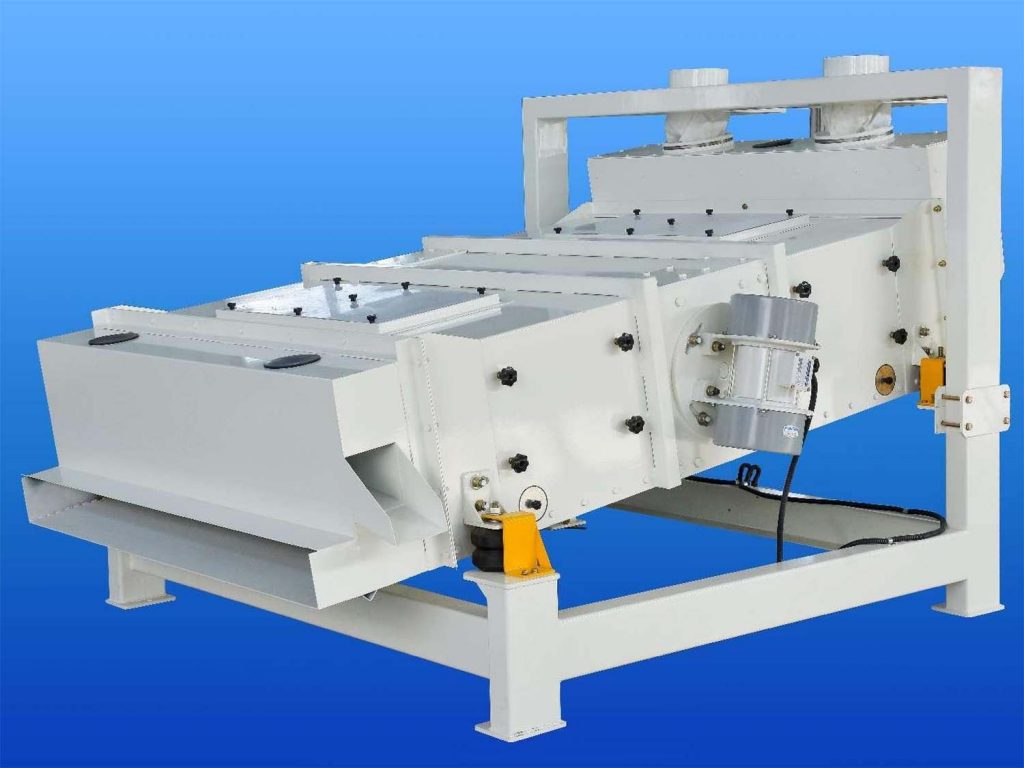

In the grain processing and storage industry, the performance of screening equipment directly affects production efficiency and grain quality. As a favored screening device for grain silo enterprises, the self balancing vibrating screen stands out due to its unique working principle.

Vibration Source and Interaction of Excitation Force

Ingenious Design of Dual-Axis Exciters

This design allows the excitation forces generated by two eccentric weights to interact, forming a stable reciprocating excitation force. This force drives the screen body to move linearly, achieving efficient material screening. Compared to traditional single-axis vibrating screens, the dual-axis design enhances the stability and uniformity of the excitation force and increases reliability when handling large volumes of material.

Precise Control of Excitation Force

The magnitude and direction of the excitation force are key factors affecting screening effectiveness. The self balancing vibrating screen can precisely control the excitation force by adjusting the vibration motor speed and the mass of the eccentric weights. In practice, operators can flexibly adjust the excitation force based on the characteristics of different grain materials and screening requirements to achieve optimal screening results.

Material Movement on the Screen Surface

Impact of Screen Surface Vibration Characteristics on Material Movement

The vibration characteristics of the screen surface directly determine the movement and screening effectiveness of the material. The screen surface of the self balancing vibrating screen performs a stable and uniform linear reciprocating motion under the action of the excitation force. This vibration pattern causes grain material to periodically jump and slide on the screen surface, achieving particle size grading.

Synergistic Screening Mechanism of Material Throwing and Sliding

During screen surface vibration, material particles experience a combined motion of throwing and sliding due to the excitation force and gravity. This alternating motion of throwing and sliding continuously loosens, flips, and redistributes the material on the screen surface. It increases the contact opportunities between the material and screen holes, facilitating the passage of different particle sizes through the screen holes for efficient screening separation.

Multi-Layer Screen Mesh Grading Screening Mechanism

Layout and Function of Multi-Layer Screen Mesh

The self balancing vibrating screen typically features multi-layer screen mesh for multi-stage grading of grain material. The screen meshes are arranged with decreasing hole sizes from top to bottom, with each layer separating material within a specific particle size range. As material enters the screen box, it passes through each layer of screen mesh in sequence under the action of screen surface vibration, ultimately achieving precise grading of different particle sizes.