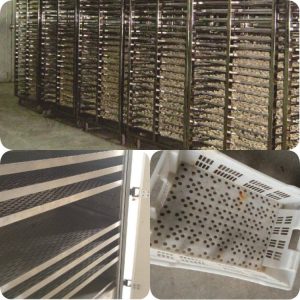

It is mainly used for drying cassava chips, sweet potato, Chinese yam, alfalfa and some flaky materials.

The heat-pump drying oven is suitable for drying materials that are mainly resistant to range of temperatures between 20-80°C during the drying process, or although the tempurature tolerates higher, but the use of a heat pump to dry more energy-efficient or safe materials. Such as: wood, cereals, seeds, edible fungi, medicinal herbs, seafood, preserved meat, fruits and vegetables, tobacco leaves, paper buddhas and so on.

1. Wide temperature range, high energy efficiency

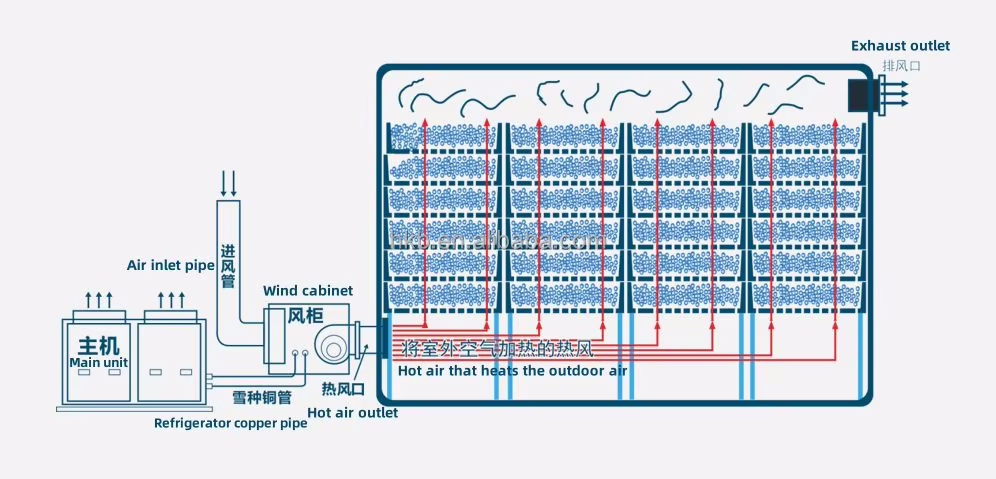

Adopt the most advanced low-temperature jet enthalpy increase technology to ensure that the unit maintains high energy efficiency and strong heating capacity under low temperature conditions.

2. High-energy display control

Adopt 7-inch industrial LCD screen for full automatic control, easy to operate.

3. High-precision configuration

High-precision electronic temperature and humidity sensor, with ultra-fast response, strong anti-interference ability, compact structure, extremely low power consumption and ultra-long transmission distance, etc., exempting users from the work of post-maintenance.

4. Efficient heat recovery

After the fresh air and exhaust air enter the heat recovery device, the large amount of waste heat released to the outside world by the drying room during dehumidification is recovered through heat exchange, and the heat recovery efficiency is as high as more than 60%.

5. Modular splicing

The modular design of the unit makes the design of the drying room and the matching of the number of units more flexible. Transportation, installation and disassembly are simpler and more efficient.

Heat pump dryer is widely used and not affected by the climate, drying materials health and environmental protection, protect the quality of materials and color luster. Heat pump drying oven is used for various of materials drying, such as fruit and vegetable, flower, tea leaf, cassava, and traditional Chinese herbal, agricultural and sideline products, sea food, paper wood, etc.

Haokebang air energy heat pump drying room open dryer is a kind of equipment that consumes electricity to drive the compressor to work, obtains 300%~500% heat energy from the ambient air, heats the materials in the drying room, and dehumidifies the materials through fresh air to achieve material drying.

This equipment can replace the original boiler and electric heating for drying, intelligent operation, reduce labor costs, ensure drying quality, and the maximum air outlet temperature is up to 80℃. It has the characteristics of high air outlet temperature, flexible installation, and wide adaptability.

|

Model

|

RB-3P

|

RB-7P-S

|

RB-14P-S

|

|

Operating Temperature Range

|

-10°C-43°C

|

||

|

Rated Reatinng Capacity(kw)

|

10.5

|

22

|

43

|

|

Draining Capacity(kg/hr)

|

12

|

25

|

50

|

|

Host Input Power(kw)

|

2.8

|

6.5

|

13

|

|

Host Size(L*W*H)(mm)

|

1675*860*1280

|

1930*1150*1315

|

2220*1330*1555

|

|

Weight of Host(kg)

|

180

|

292

|

468

|

|

Board Room Size(L*W*H)(mm)

|

3500*2000*2200

|

5300*2200*2200

|

8400*3000*2200

|

|

6Number of Fans

|

8

|

8

|

16

|

|

Single Fan Power(kw)

|

0.25

|

||

|

Trolly Size(L*W*H)(mm)

|

1000*750*1750

|

1200*875*1750

|

1200*875*1750

|

|

Number of Trolley

|

4

|

6

|

12

|

|

Trolley Type

|

Integral/Split type

|

||

|

Trolley Material

|

Galvanized/Stainless steel

|

||

|

Tray Size(L*W*H)(mm)

|

730*430*70

|

600*800*75

|

600*800*75

|

|

Number of Trays

|

96

|

144

|

288

|

|

Tray Material

|

PP polypropylene/304 stainless steel

|

||

Henan Haokebang Machinery Equipment Co., Ltd. specializes in the production of 100-10,000 ton hopper bottom and flat bottom corrugated galvanized steel silos. According to various factors such as site, weather, and geology, we provide professional silo design, equipped with elevators, unloading pits, pre-cleaner, conveyors, sweeping auger and other accessories to meet the diverse needs of customers.