It is mainly used for drying cassava chips, sweet potato, Chinese yam, alfalfa and some flaky materials.

Mesh belt dryer is mainly used for continuous drying of materials with large capacity. It can dry most materials such as vegetables, grains, fruits, flowers and leaves, pastures, etc. It has been applied to the drying of more than 300 materials, realizing multiple functions in one machine, and bringing huge economic benefits to our customers.

1.Highly automated, large capacity and energy saving;

2.User frinedly,1-2 works needed;

3.Temparature adjusted to best preserve the nutrition;

4.Specialized devvice to spread materials evenly so as to shorten the drying cycle and reduce processing cost.

5.Mutible choices of heating source; such as coal, biomass fuel, natural gas, hot blast stove, steam heat exchanger, air energy heat pump, etc.

It is mainly used for drying cassava chips, sweet potato, Chinese yam, alfalfa and some flaky materials.

Mesh belt type drying machine main principle is the material evenly tiled on the mesh belt, is driven by the drive device in the dryer moving back and forth, hot air in materials and the cross flow, water vapour from the wet discharging hole in discharge, so as to achieve the purpose of drying. Network with 12-60 to wire mesh belt, the body length by a combination of the standard section, in order to save space, the drying mechanism into multi-layer, common has two room three and two-room five layers, length 6-40m, effective width 0.6-3.0m.

The material has the nose to enter slowly through the drying for drying, net belt line speed depending on the type of material and water content. Air flow to the use of negative pressure, porous air, to ensure the effective drying area, wind speed distribution uniformity, improve the drying effect. In order to get the best drying effect and the appropriate output, the water content of the material, the line speed of the net belt, the air volume and the air temperature must be the appropriate, reasonable and organic combination.

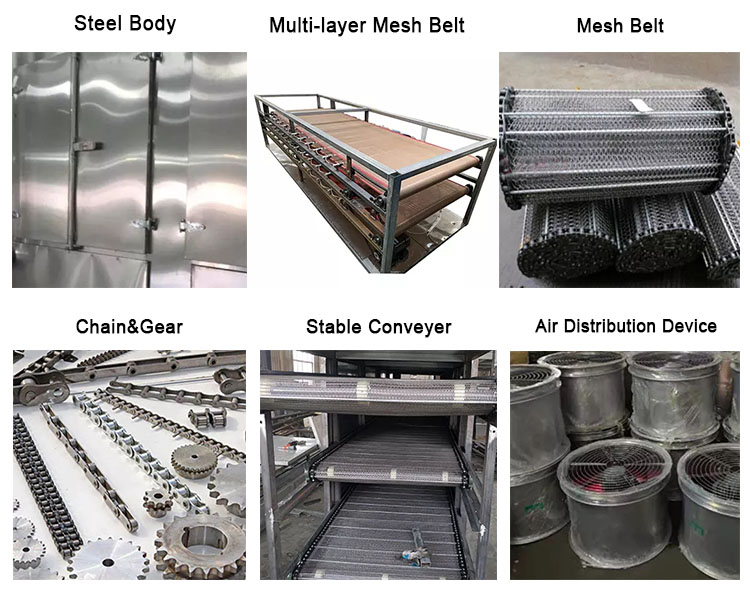

| Steel Body | Multi-layer Mesh Belt | Mesh Belt |

| Thick 304 stainless

Wear-resistant Corrosion-resistant |

High drying effciency | Stainless Steel

Corrosion resistance No rust Long service life |

| Chain&Gear | Stable Conveyer | Air Distribution Device |

| Precision alloy steel

Strong&Durable |

Simple Structure

Easy to maintain |

Hot air distribution is more even |

| Model(mm) | DW2*6-6 | DW2*6-8 | DW2*6-10 | DW2*6-12 |

| Power(KW) | 20.34 | 20.34 | 27.34 | 28.34 |

| Dimension(mm) | 6000*2100*2400 | 8000*2100*2400 | 10000*2100*2400 | 11800*2100*2400 |

| Feeding conveyor

(L*W)(mm) |

4000*1800 | 4000*1800 | 5000*1800 | 6000*1800 |

| Discharging conveyor

(L*W)(mm) |

5000-300 | 5000*300 | 5000*300 | 5000*300 |

| Dimension for stove

(L*W*H) |

2800*1550*2200 | 2800*1550*2200 | 3400*1680*2200 | 3400*1680*2200 |

Henan Haokebang Machinery Equipment Co., Ltd. specializes in the production of 100-10,000 ton hopper bottom and flat bottom corrugated galvanized steel silos. According to various factors such as site, weather, and geology, we provide professional silo design, equipped with elevators, unloading pits, pre-cleaner, conveyors, sweeping auger and other accessories to meet the diverse needs of customers.