The self balancing vibrating screen, as a vital device in the grain screening field, has its design rationality directly determining screening efficiency and quality. To meet the market's demand for efficient and precise screening equipment, it is crucial to delve into the design philosophy and key points of the self balancing vibrating screen.

Design Principles

Function-Oriented

The design of the self balancing vibrating screen centers on meeting the functional needs of grain screening. It takes into account the characteristics of different grain varieties, such as particle size, shape, and specific gravity, to achieve precise grading.

Durability and Reliability

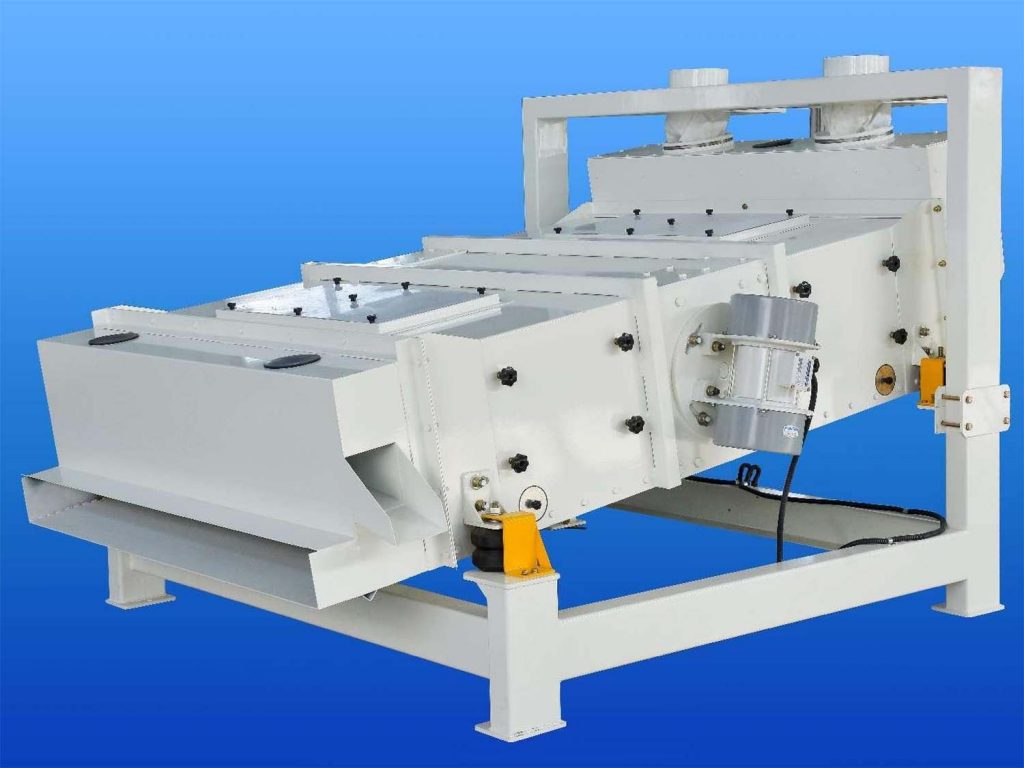

Given the high-intensity working environment of grain screening, the design of the self balancing vibrating screen prioritizes structural durability and operational reliability. The overall structure uses high-quality steel to ensure stability during long-term, high-intensity vibration screening. Key components like vibration motors and vibration-dampening rubber springs undergo strict selection and durability testing to reduce the incidence of faults.

Structural Design

Vibration System Design

The vibration system design of the self balancing vibrating screen is the core of achieving efficient screening. It employs a dual-axis exciter design, generating a stable reciprocating excitation force through counter-rotating shafts to drive the screen box vibration. This design ensures more uniform and stable vibration, guaranteeing even distribution and movement of material on the screen surface.

Screen Mesh Support Structure

The design of the screen mesh support structure directly affects the tension state and screening precision of the mesh. The self balancing vibrating screen uses a modular frame design with a box-beam structure for the overall frame, ensuring high installation plane accuracy for the screen mesh. Rational support and tensioning devices enhance screening efficiency and screen mesh lifespan, reducing replacement costs.

Design Optimization

Vibration and Noise Reduction

During the design process, the self balancing vibrating screen incorporates vibration and noise reduction measures. By using vibration-dampening rubber springs and optimizing the overall structure, it effectively reduces vibration transmission and noise generation during operation. This not only improves equipment stability but also enhances the working environment.

Intelligent Design

To adapt to the trend of modern industrial intelligence, the design of the self balancing vibrating screen integrates intelligent control elements. Equipped with sensors to monitor key parameters such as vibration frequency, amplitude, and motor temperature, it achieves real-time monitoring and fault early warning through an automated control system. This helps timely adjust the equipment's operating condition, improving production efficiency and equipment lifespan.