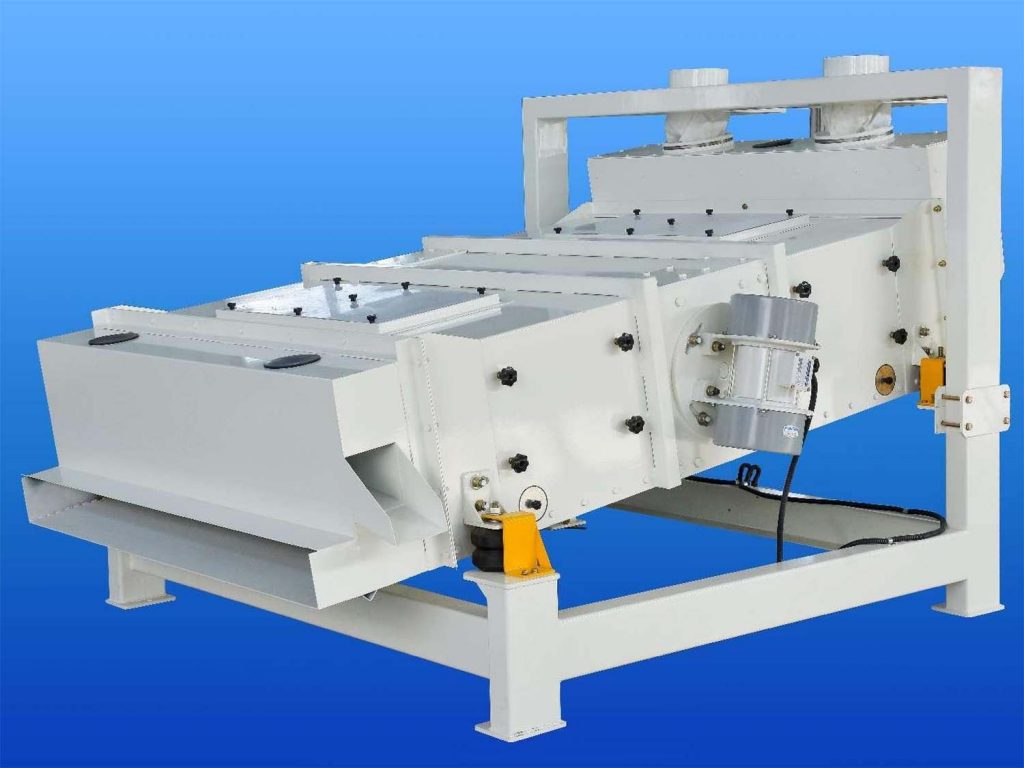

The vibrating screen is a key device for ensuring grain quality and storage safety. It removes impurities and inferior grains through efficient screening, laying a solid foundation for grain storage and further processing. This article will explore the role of vibrating screen.

Vibrating Screen Enhances Grain Quality

Accurate Separation of Impurities and Quality Grains

The role of vibrating screen includes separating impurities. When large amounts of grain flow into the silo, stones, soil, metal fragments, and broken grains mixed in can severely affect grain quality. The vibrating screen, with its unique vibration principle, can accurately separate these impurities and inferior grains.

Optimizing Grain Grade Classification

In addition to removing impurities, the vibrating screen can also classify grain finely. Different uses of grain have different requirements for particle size and shape. The vibrating screen, through multi-layer screens and precise vibration parameter settings, can accurately separate grain by grade.

How Vibrating Screen Ensures Grain Storage Safety

Eliminating Fire Hazards

The role of vibrating screen also includes ensuring grain safety. Conductive impurities such as metal fragments, when mixed into the grain pile, can easily spark during grain compression and friction, potentially causing fires. The vibrating screen can efficiently intercept these metal fragments, eliminating fire hazards at the source and ensuring the fire safety of the grain silo.

Inhibiting Microbial Growth

Soil and organic impurities are breeding grounds for bacteria and mold. If these impurities mix into the grain pile, under suitable temperature and humidity conditions, they can easily cause grain to mold and deteriorate, resulting in significant losses. By removing these potential hazards, the vibrating screen effectively inhibits the growth and reproduction of microorganisms, ensuring grain safety during storage and extending the shelf life of grain.