Working Principle of Vibrating Screen

The efficient screening capability of a vibrating screen mainly originates from its working principle. A deep understanding of this principle helps us better utilize vibrating screens for material screening.

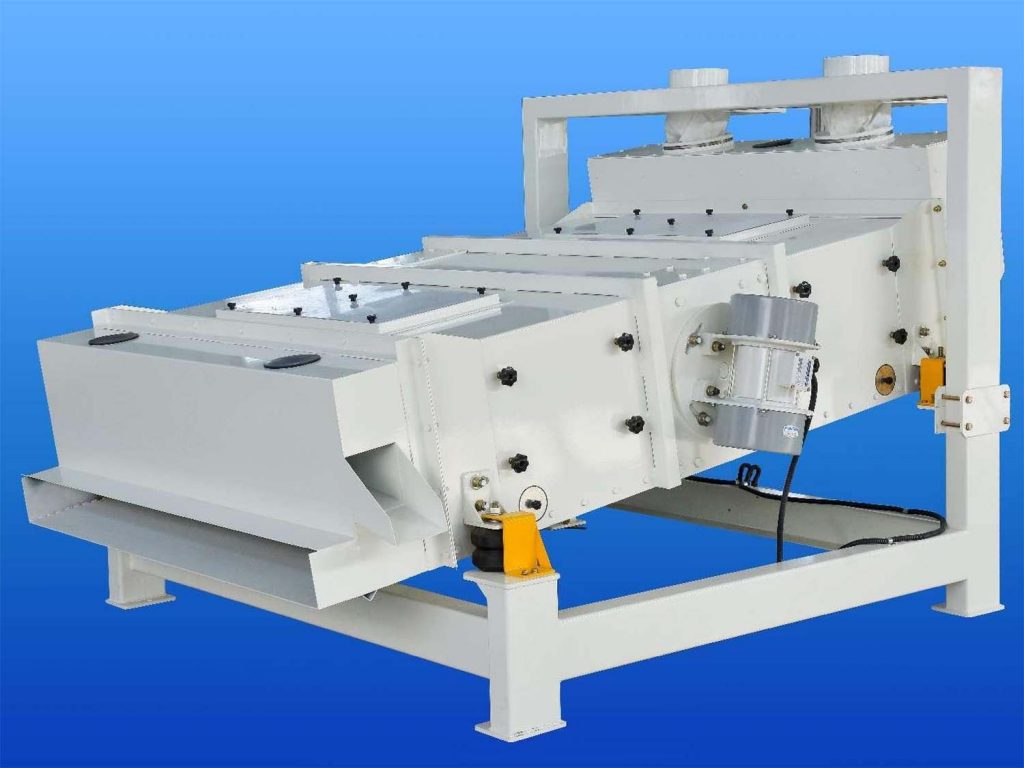

The working principle of the vibrating screen is based on the periodic vibration of the screen box to achieve material screening. The motor drives the screen box to vibrate at a certain frequency and amplitude through the vibrator. This vibration causes the material to move in a near-circular trajectory on the screen surface, thus achieving material stratification and separation.

Vibration frequency and amplitude are key parameters in the working principle of vibrating screens. A higher frequency allows the material to roll and separate more quickly on the screen surface. An appropriate amplitude helps overcome the friction between the material and the screen surface, promoting material flow.

Under the influence of vibration, the material continuously rolls, jumps, and moves forward on the screen surface. Fine particles smoothly pass through the screen holes and fall into the collection device. Larger particles and impurities remain on the screen surface and are discharged through the outlet. This vibration screening process can accurately classify materials based on their particle size and shape, ensuring the accuracy and consistency of the screening results.

The working principle of the vibrating screen is not only reflected in its basic vibration mechanism but also in how to optimize the design to improve screening efficiency.

The screen mesh is a core component of the vibrating screen, and its mesh size and quality directly determine the screening accuracy. Choosing a screen mesh with the appropriate mesh size is the foundation for precise screening. The quality of the screen mesh affects its durability and screening performance.

The working principle of the vibrating screen allows it to be equipped with multi-layer screen meshes for simultaneous screening of materials with different particle sizes. Each layer of screen mesh is arranged according to particle size. Under the action of vibration, the material is screened layer by layer, ultimately achieving multi-level classification..