Grain dryer is suitable for efficient drying all cereals, grains, beans and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable to all kinds of farm.

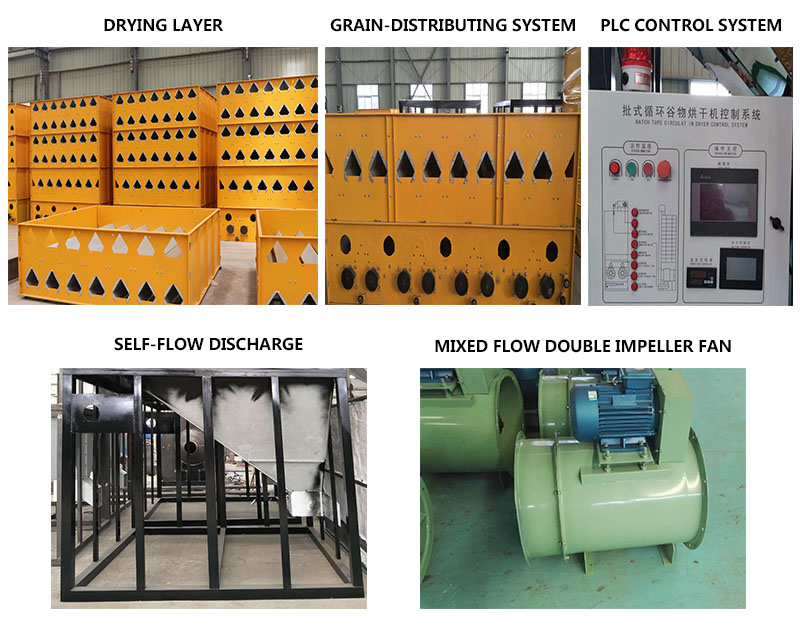

Haokebang 5H-KB low temperature batch circulation grain drying machine is an ideal drying equipment for drying grains. Cereals such as peanuts. It adopts multifunctional machine design, indirect hot air heating, large capacity, and increases the drying layer area.

Due to the ingenious structural design, the required power is reduced, and the drying efficiency is improved on the basis of saving space and energy for users.

The use of thegrain drying machine can effectively reduce the drying rate of grain and grain, and improve the grain accuracy, thereby improving the quality of grain and grain.

Grain drying machine Dry different materials without replacing parts; electrostatic spray.

– High thermal efficiency, low unit energy consumption and high productivity.

– Uniform heat, low thermal damage, low breakage rate, full and complete particles, high seed germination rate.

– Environmentally friendly hot blast stove, low noise, weak vibration, fuel saving, low cost (rice husk, corn cob, diesel, coal, etc. can be used as its fuel) and long service life.

– Easy to disassemble and ship, occupying a small area and low labor operation intensity.

– Simple structure, high quality and low price, low investment cost and no site restrictions.

– The combustion chamber is made of 310s high temperature resistant stainless steel.

– PLC control box, fully automatic control system, touch screen display, easy to operate.

Grain drying machine is suitable for efficient drying all cereals, grains, beans and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable to all kinds of farm.

The grain drying machine is an ideal paddy drying equipment for grain drying machine and oil crops. The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward and the multi-row V-shaped baffles arranged staggered for processing,so that the rice crops can be mixed with the hot air, and also serve as a the inlet and outlet channels of drying air, most of the drying air can be recycled, and the water vapor generated when the material is dried is discharged from the dryer exhaust system, so the fuel consumption is very small.

How do we assure the grain dryer solidity?

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |

| Dryer type | Batch type recirculating mixed flow drying | |||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |

| Overall weight(kg) | 5000 | 6000 | 9500 | |

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |

| Power(kw) | 8.7 | 8.7 | 13.5 | |

| Bunner | Type | Indirect Type | ||

| Ignition method | Manual Ignition | |||

| Fuel consumption

(kg/h) |

≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||

| Moisture Reduction per hour

(%/h) |

Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||

Henan Haokebang Machinery Equipment Co., Ltd. specializes in the production of 100-10,000 ton hopper bottom and flat bottom corrugated galvanized steel silos. According to various factors such as site, weather, and geology, we provide professional silo design, equipped with elevators, unloading pits, pre-cleaner, conveyors, sweeping auger and other accessories to meet the diverse needs of customers.